Sandy Curth

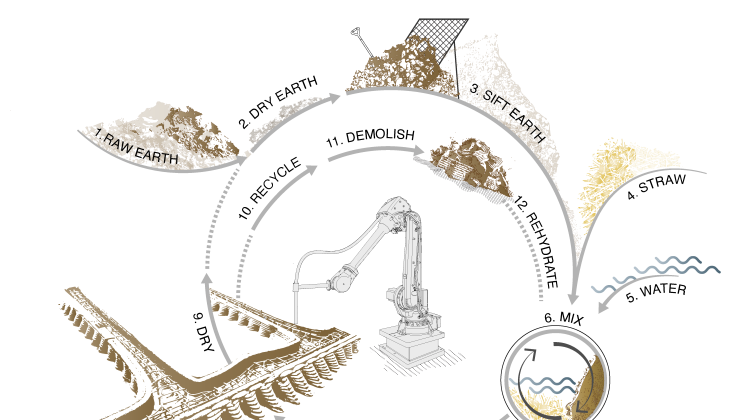

I am a designer and computational researcher focused on developing tools for democratization and access in the world of architectural additive manufacturing. I work at the intersection of material science, robotics, and structural optimization to create design/fabrication methods for rapidly deployable, climate-resilient housing. In practice, this generally looks like designing and 3D printing buildings and building elements with locally sourced earthen materials.

Currently, I am a PhD candidate in the Design and Computation Group at MIT where I lead the Programmable Mud Initiative, advised by Dr. Larry Sass. At MIT I have been fortunate to collaborate with and receive support from Digital Structures, the Huang Hobbs Biomaker Space, and the Center for Bits and Atoms.

Previously I completed a Master of Architecture at UC Berkeley where I designed and built full-scale 3D printed earthen architecture with Emerging Objects, printed lightweight spanning structures with the Flexible Structures Lab, and developed AR/VR compatible digital fabrication strategies with the XR Lab. I was a 2019 Norman Foster Foundation Robotics Scholar. I completed undergraduate degrees in Physics and Anthropology at Bennington College.

Beyond architecture, I have worked on the Long Now Foundation's 10,000 Year Clock Project, shucked a lot of oysters for Hog Island Oyster Co. and run my hometown’s annual Christmas Bird Count, part of the world’s largest, longest running citizen science project.

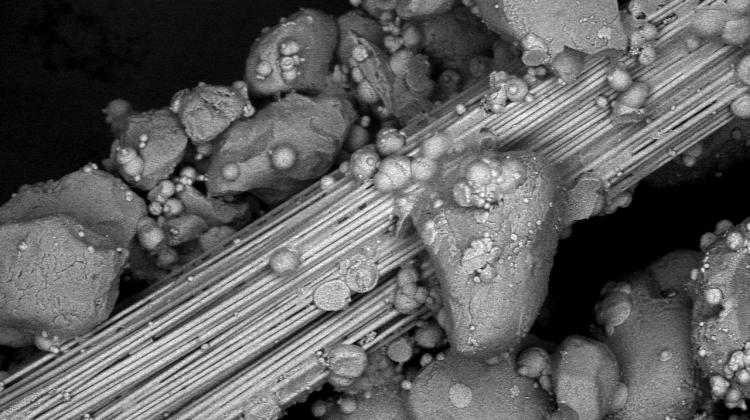

How do we design with microbes?

Can we make high-performance building materials with nothing more than the ground beneath our feet?

Collaborators: Laura Gonzalez

Supported by: The Programmable Mud Initiative, Huang Hobbs Biomaker Space, MIT Biological Engineering, MIT Architecture